Liuan, Anhui Feb 4, 2026 (Issuewire.com) - The Evolving Landscape of Thermal Management and Industrial Inspection

In the modern industrial landscape, the integrity of thermal management systems is paramount, particularly as high-power computing and electric vehicle infrastructures expand globally. One of the most critical aspects of ensuring this integrity is Professional Non-destructive Testing for Liquid Coolers from China, a field that has seen significant technological leaps in recent years.

The global manufacturing sector is currently witnessing a paradigm shift driven by the "Green Revolution" and the digitalization of industry. As data centers, energy storage systems, and high-performance electronics become more dense, traditional air cooling is no longer sufficient. Liquid cooling has emerged as the gold standard for efficient heat dissipation. However, the adoption of liquid cooling brings an inherent risk: the proximity of conductive fluids to sensitive electronic components. This risk has catalyzed a massive surge in demand for high-precision leak detection. For this reason, non-destructive testing has been widely promoted.

Non-destructive testing (NDT) refers to a group of analysis techniques used in science and technology industries to evaluate the properties of a material, component, or system without causing damage. For liquid coolers, which must operate under pressure without leakage for extended lifecycles, NDTspecifically vacuum helium leak detectionserves as the ultimate safeguard. By identifying microscopic defects that could lead to catastrophic failures, these testing protocols ensure that liquid cooling units meet the rigorous safety and performance standards required by international markets.

Unique Competitive Advantages in Liquid Cooler Production

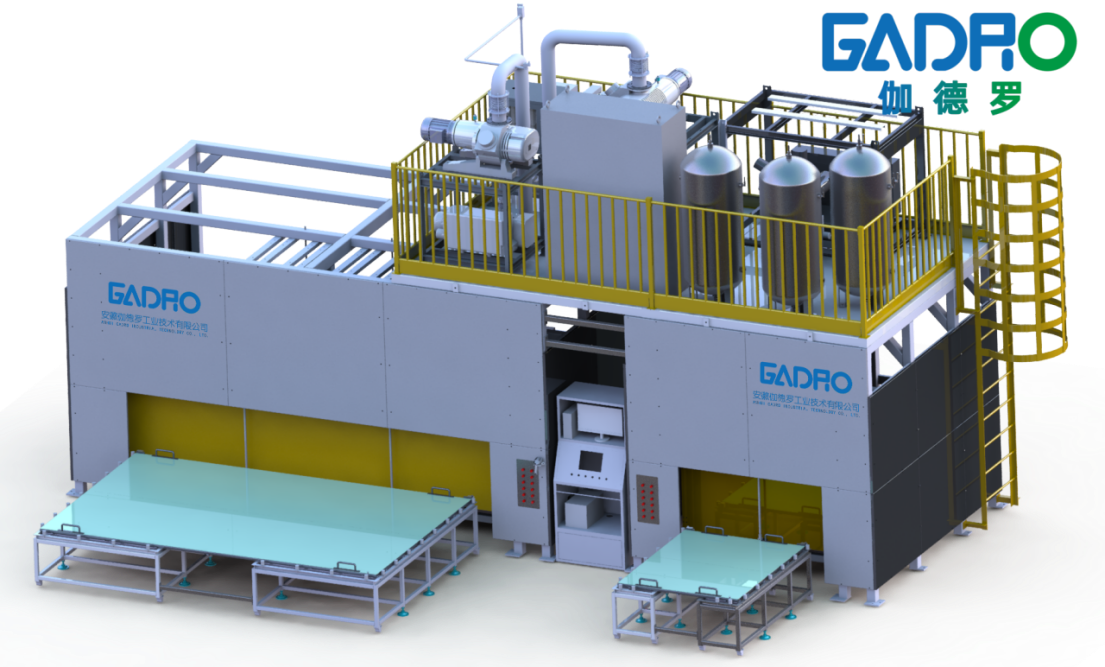

The core competitiveness of modern leak detection lies in its precision and adaptability. Gadros customized helium detection equipment for liquid coolers utilizes vacuum chamber technology to achieve sensitivities that are unattainable by traditional air-under-water or pressure decay methods. This level of precision is critical for liquid plates used in electric vehicle batteries or server cold plates, where even a "micro-leak" over several years could lead to system failure.

The ascendancy of helium leak detection as the professional standard in China and the global high-end manufacturing sector is driven by its transformative impact on both production efficiency and uncompromising quality assurance. As thermal management becomes increasingly critical for sectors like electric vehicles and data centers, the "premium product" philosophy of Anhui Gadro Industrial Technology Co., Ltd. ensures these systems are not merely tools, but integrated technical solutions.

l Technical Superiority and Industry-Leading Sensitivity

The fundamental advantage of this methodology lies in its High Sensitivity. Helium molecules possess an extremely small atomic radius and remain chemically inert, making them the ideal tracer gas for penetrating microscopic structural defects. Unlike traditional air-under-water (bubble) testing or pressure decay methodswhich are often limited by surface tension or thermal fluctuationsGadros customized helium detection technology can identify leak rates as low as 1 × 10¹ mbar·l/s. For liquid-cooled plates, this precision is vital to prevent "micro-leaks" that could lead to catastrophic cooling failure over years of service in high-stakes environments.

l Optimized Production Rhythm and Fast Response

In a modern industrial setting, speed is as critical as accuracy. The Fast Response of helium detection technology allows it to react to leaks within a very short period. This efficiency is a cornerstone of Gadros automated production line solutions, which are designed to match the high-speed "production rhythm" (measured in seconds per piece) required by global manufacturers. By minimizing the time required for vacuum stabilization and signal analysis, the system ensures that high-precision inspection does not become a bottleneck in the smart factory workflow.

l Non-Invasive Preservation of Component Integrity

The Non-Invasive nature of this non-destructive testing (NDT) ensures that the liquid coolers remain completely unaffected by the inspection process. There is no risk of moisture contamination (as seen in water-submersion tests) or physical deformation from excessive air pressure. This preserves the original high-performance state of the heat dissipation surfaces and internal channels, ensuring the product delivered to the end-user is pristine.

l Intuitive Visualization and Data Integration

Modern systems have moved beyond simple alarms to offer Intuitive Visualization. By displaying real-time helium concentration levels, the technology provides a clear digital representation of the leak's magnitude. This data is not just for immediate rejection; it feeds directly into Gadros industrial Internet big data platforms. Manufacturers can analyze these digital footprints to identify trends in production defects, enabling preemptive maintenance and continuous process optimizationa key feature of the "digital smart factory".

Navigating Global Standards: The Significance of CE Machinery Directive Compliance

For any industrial equipment to gain a foothold in the international market, particularly within the European Economic Area, adherence to stringent regulatory frameworks is mandatory. The CE Machinery Directive (2006/42/EC) serves as one of the most authoritative benchmarks for equipment safety and reliability. Achieving CE Machinery Directive Compliance is not merely a legal formality; it is a testament to the engineering excellence and safety consciousness of a manufacturer. For leak detection systems used in liquid cooler production, this certification confirms that the machinery meets essential health and safety requirements, covering everything from mechanical stability and electrical safety to the mitigation of pressurized hazards.

Market recognition is often tied directly to these certifications. When a testing system carries the CE mark, it signals to global Tier-1 suppliers and OEMs that the equipment has undergone rigorous risk assessments and technical evaluations. In the context of liquid cooler manufacturing, where a single leak can result in millions of dollars in equipment damage, the authority of CE compliance provides the necessary assurance for long-term partnership. It bridges the gap between regional manufacturing and global acceptance, allowing advanced Chinese NDT solutions to be integrated into the most demanding production environments across Europe and the Americas.

For more information on advanced leak detection solutions and industrial NDT technology, please visit the official website: https://www.gadrodetection.com/

Source :Anhui Gadro Industrial Technology Co., Ltd.

This article was originally published by IssueWire. Read the original article here.