Shenzhen, Guangdong Dec 9, 2025 (Issuewire.com) - In the fast-paced world of electronics innovation, the need for speed, precision, and flexibility has never been greater. As product development cycles shorten and competition intensifies, China low volume PCB assembly has emerged as a crucial enabler for rapid prototyping and small-batch production. This approach allows engineers and startups to validate designs, optimize performance, and bring new electronic products to market faster than ever before.

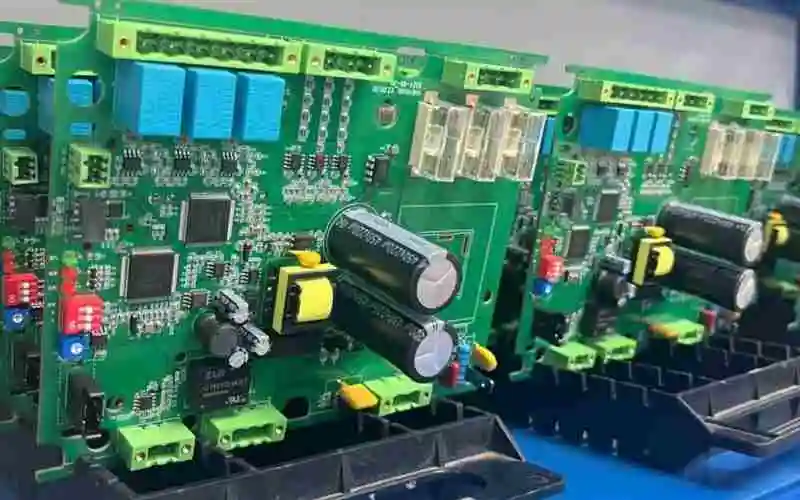

FR4PCB.TECH, a leading provider of advanced PCB (Printed Circuit Board) manufacturing and assembly services, is at the forefront of this transformation. Specializing in OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) solutions, the company offers a full spectrum of servicesfrom design verification and DFM (Design for Manufacturability) analysis to PCB fabrication, component sourcing, SMT (Surface-Mount Technology) assembly, through-hole assembly, testing, and logistics. By focusing on low-volume PCB assembly, FR4PCB.TECH empowers innovators worldwide to accelerate product development while maintaining cost efficiency and manufacturing reliability.

Industry Outlook and Trends1. The Shift Toward Agile Electronics Manufacturing

Traditional high-volume production once dominated the electronics industry, but the market is now driven by customization, speed, and innovation. Businesses developing IoT devices, medical instruments, or consumer gadgets increasingly require smaller production runs to test product-market fit before scaling up. China low volume PCB assembly allows manufacturers to produce limited quantities quickly and affordably, reducing development risk and improving iteration efficiency.

This agile manufacturing model has become especially valuable for startups and R&D departments that must frequently modify designs based on user feedback or new technological developments. Instead of investing heavily in large-scale production, companies can now prototype and refine more effectively.

2. Faster Time-to-Market and Design Validation

In industries where innovation cycles can determine success or failure, rapid prototyping supported by low-volume PCB assembly provides a decisive competitive edge. Engineers can test circuits, evaluate thermal performance, and confirm component compatibility within days rather than weeks.

FR4PCB.TECHs quick-turn assembly services, combined with precision SMT equipment and automated testing processes, help clients move from concept to functional prototype in record time. This ability to shorten product development timelines allows businesses to meet demanding market schedules without compromising on quality.

3. The Rise of Customization and Specialized Electronics

Consumer expectations for personalized technology are reshaping the electronics industry. Products such as wearable devices, smart home solutions, and specialized industrial equipment often require custom PCBs built to unique form factors. Low-volume assembly enables the production of these specialized boards without the high costs typically associated with mass production setups.

Chinese manufacturers like FR4PCB.TECH play a pivotal role in this evolution by combining flexible production lines with experienced engineering support. As a result, clients can achieve both precision customization and scalable production when demand grows.

4. Cost Optimization and Supply Chain Efficiency

Low-volume PCB assembly in China offers an optimal balance between affordability and quality. By leveraging mature supply chains, advanced SMT automation, and efficient component sourcing, companies can minimize waste and reduce per-unit costs, even for small production runs.

FR4PCB.TECHs expertise in BOM (Bill of Materials) optimization helps clients select cost-effective components without sacrificing reliability. Moreover, proximity to global component suppliers enables shorter lead times and enhanced flexibility for last-minute design changes.

5. Quality Assurance and Certification Standards

While low-volume production is often associated with prototyping, maintaining high reliability remains essential. FR4PCB.TECH integrates rigorous testing proceduresincluding AOI (Automated Optical Inspection), X-ray analysis, and functional verificationto ensure that every board meets international standards.

The companys ISO 9001 certification and IPC Class 2/3 compliance ensure consistent product quality across both prototype and production phases. This certification-backed approach gives clients confidence that their early-stage prototypes will perform as reliably as full-scale production units.

FR4PCB.TECH: Expertise, Achievements, and Applications1. Company Background and Vision

FR4PCB.TECH was founded with the mission to deliver superior PCB manufacturing and assembly solutions that meet the evolving needs of global electronics innovators. With years of industry experience, the company has become a trusted partner to businesses across consumer electronics, automotive systems, telecommunications, medical technology, and industrial automation.

The companys focus on OEM and ODM services allows clients to benefit from comprehensive, end-to-end production capabilitiesspanning initial design consultation through to fully tested and packaged assemblies ready for deployment.

2. Core Capabilities

FR4PCB.TECHs technical capabilities include:

Advanced PCB Fabrication: Multilayer, HDI, and flexible PCB production with tight tolerances.

SMT & Through-Hole Assembly: Automated precision assembly for both prototypes and production batches.

DFM & Engineering Support: Expert design analysis to improve manufacturability and reduce costs.

Component Sourcing & BOM Optimization: Access to global supply chains for reliable component procurement.

Testing & Quality Control: AOI, ICT, and functional testing ensure flawless performance.

Logistics & Final Assembly: Seamless integration from manufacturing to shipping.

Through these services, FR4PCB.TECH ensures every projectfrom prototype to full-scale productionbenefits from efficiency, consistency, and transparency.

3. Certifications and Industry Recognition

FR4PCB.TECH operates under ISO 9001 quality management certification, adheres to IPC Class 2/3 assembly standards, and maintains RoHS compliance. These credentials demonstrate its dedication to maintaining quality, safety, and environmental responsibility across all production processes.

The companys emphasis on continuous improvement has earned it recognition as a trusted partner in China low volume PCB assembly, known for delivering precision and dependability at every project stage.

4. Product Applications and Client Success Stories

FR4PCB.TECHs assemblies are used in a wide variety of applications, including:

Consumer Electronics: Smartwatches, Bluetooth audio devices, and home automation systems.

Medical Devices: Portable monitors, diagnostic sensors, and imaging components.

Automotive Electronics: Control modules, sensor systems, and infotainment interfaces.

Telecommunication Equipment: Routers, base stations, and data communication modules.

Industrial Automation: PLC controllers, sensor arrays, and robotics systems.

A notable success story includes collabortion with a European IoT startup that required rapid prototyping of smart sensor boards. FR4PCB.TECH delivered functional prototypes within five business days, enabling the client to secure investor funding and move to pilot production within a month.

Another case involved a North American medical device company seeking highly reliable low-volume PCB assemblies for regulatory testing. FR4PCB.TECHs ISO-certified process ensured consistent quality, helping the client achieve FDA compliance on the first submission.

5. Driving the Future of Electronics Prototyping

By integrating advanced automation, experienced engineering teams, and flexible production systems, FR4PCB.TECH continues to redefine whats possible in rapid electronics prototyping. The companys focus on collaboration and efficiency enables customers to turn ideas into products fasteran essential advantage in todays innovation-driven markets.

Conclusion

As global electronics markets continue to evolve, China low volume PCB assembly stands out as a key driver of innovation and agility. FR4PCB.TECHs commitment to quality, speed, and client collaboration makes it a preferred partner for businesses aiming to transform concepts into successful products.

Through ISO-certified processes, comprehensive OEM/ODM support, and proven success across multiple industries, FR4PCB.TECH demonstrates how precision manufacturing and low-volume flexibility can reshape the future of electronic design and development.

For more information about FR4PCB.TECH and its full range of PCB manufacturing and assembly services, please visit https://www.fr4pcb.tech/.

Source :Shenzhen Xindachang Technology Co.. Ltd

This article was originally published by IssueWire. Read the original article here.